COMPLIANCE

WE GO BEYOND THE LIMITS...

Fire resistant doors (known as fire doors) are used to protect people and property. SANS 1253 specifies requirements for six classes of fire door and fire-shutter ASSEMBLIES that are intended to close permanent openings in walls or partitions, to provide a fire resistance of at least 30 min in order to stop the spread of fire and to limit the spread of smoke.

Bear in mind that a fire could be on either side of a fire door, therefore it is vitally important that the door be tested on the face of weakest performance, and that is the face which OPENS IN to a fire.

So what defines a fire door?

Standards set out by the South African Bureau of Standards (SABS) must be satisfied by all fire door manufacturers and these are found in detail in the following three codes being:

SANS 1253:2016 ED3.1

Fire doors and fire-shutters. Here is where you will find the fine detail that fire doors must adhere to.

SANS 10177-2

Fire testing of materials, components and elements used in buildings – Part 2: Fire resistance test for building elements.

SANS 10400-T

The application of the National Building Regulations Part T: Fire protection.

our testing

At CRISIS FIRE DOORS we have extensively tested and passed both our Class A and Class E fire doors on both sides and the OPEN IN being the most important, including essential hardware for the hospitality industry, being:

– Concealed door closer

– Door viewer (Peephole)

– Access control locks (Vingcard, Salto & Dormakaba)

– Concealed drop-seal

– Certifire hinges

– Acoustic frame perimeter seals

– Intumescent fire and smoke seals

ONLY FROM

CRISIS FIRE DOORS

OUR TEST VIDEOS

Follow our YouTube channel to view our series of clips relating to fire testing.

Our first episode is how we gather data for research and development of our FIREMAN™ CLASS A & our FIREFIGHTER™ CLASS E both have passed the most stringent and difficult fire test in the industry, the “OPEN IN” test.

CRISIS FIRE DOORS are the only manufacturer in Africa to have passed this test.

SANS 1253:2016 ed3.1

- Testing criteria.

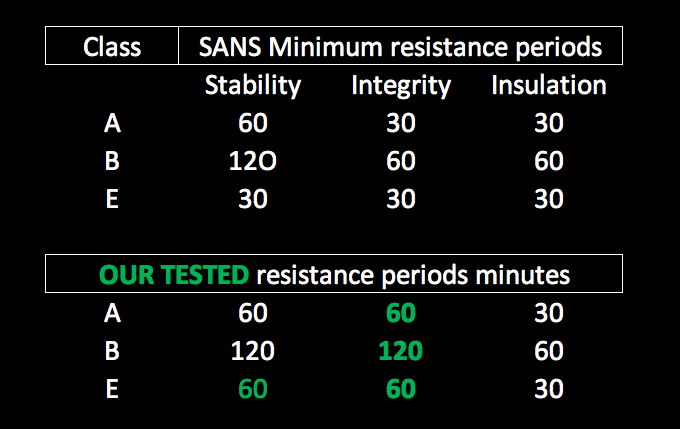

Testing revolves around Stability, Integrity and Insulation.

SANS defines that when a fire-door ASSEMBLY is tested in accordance to STABILITY, INTEGRITY and INSULATION, it shall, for at least the appropriate minimum periods given in the criteria table, comply with the requirements given in the points below

4.9.2.1 – The door or ASSEMBLY shall withstand the prescribed fire exposure and effectively close an opening without the doors moving out of the frame by more than 25mm.

4.9.2.2 -There shall be no flaming on the unexposed face of the door ASSEMBLY within the first 30 minutes of the classification period.

4.9.2.3 – Intermittent light flames of approximately 150mm long may occur for periods not exceeding 5 minute intervals along the edges of the door after 30 minutes.

4.9.2.4 – Light flaming may occur during the last 15 minutes of the classification period on the unexposed face area of the door, provided it is contained within a distance of 40mm from a vertical door edge and within 75mm from the top edge of the door and within 75mm from the top edge of the frame of a viewing panel.

The door or ASSEMBLY shall withstand the presicribed fire exposure wihout the development, at any point of the door, of

a) a straight-through gap of width that exceeds 10mm, and

b) straight-through gaps of width that exceeds 6mm, but does not exceed 10mm and of combined length that exceeds the greater of the width or height of the door.

The door or ASSEMBLY shall withstand the prescribed fire exposure without the mean temperature of the unexposed face rising to more than 140 ºC initial ambient temperature, or the temperature at any point of the face rising to more than 180 ºC above initial temperature.

- manufacturing criteria

SANS also defines that a fire door must be a complete ASSEMBLY including ironmongery when tested to replicate the “real-world” installation. As a manufacturer we comply to this standard, we test with ironmongery.

describes a fire door. It must be noted that the door is an ASSEMBLY inclusive of the frame and hardware. A door leaf is a part that hangs on the frame or is alternatively described as the moving part. There is thus no doubt that a fire-door test includes the ENTIRE COMBINATION of frame, fixing type, door leaf and essential hardware to be built into the test furnace to resemble the final installation on the fire-door.

of SANS 1253 defines a fire door ASSEMBLY as a door and its essential hardware so mounted on a frame that the required fire resistance is provided.

clearly states a fire door ASSEMBLY shall be of fire resistance A, B, C, D, E or F, as required.

sans 1253 simplified:

Simply put it says that all fire doors must be tested as an ASSEMBLY, which is made up of the frame, door, hinges, lock and handle and any other item that you may want to install.

Should you install a fire door that has been tested without these essential parts your site is at RISK that the final door assembly won’t perform as required and your insurer may not wish to extend cover as the fire door is according to the code, non-compliant.

Manufacturers are ethically and duty bound to comply to these SANS codes in full to ensure protection of your property and safety of people.

SANS 10177-2

fire door criteria

This code is referenced in the National Building Regulations and Building Standards Act and covers the method of test used to determine the fire resistance of any element in a building, on the basis of the length of time within which the test specimen of specified dimensions will satisfy the criteria in respect of stability, integrity, and insulation.

In respect of fire doors two sections to take note of are section 1.1 SCOPE and section 3.5.1 POSITIONING which define two critical conditions that must be present when tested. The fire door must be an ASSEMBLY and it must be tested either from both sides or from the weakest side.

g) door and shutter ASSEMBLY

So position and secure the specimen under test that:

b) in the case of a test specimen of an element that has the function of separating spaces; heat will be applied over the whole of one face only, the selection of that face being as follows:

2) if the element may be required to resist fire from either direction, the heat will be applied in the direction considered, by the testing authority, to give the lower resistance (in cases of doubt, each face should be tested on separate specimens)

sans 10177 simplified:

Not all fire doors are created equal. Therefore its obvious that ALL fire door assemblies must be tested as a complete ASSEMBLY regardless of the class.

In order to truly provide protection they must be tested on the weakest side, which is clearly the OPEN IN side toward the fire. Should your fire door be of Class E or Class A and it is being used to separate an occupancy then it must be tested OPEN IN. All fire testing laboratories and fire chiefs will confirm this for you.

The only exception is for fire escape route doors, which are Class B fire door assemblies and are tested open out which is sufficient. If however they are used as dwelling separation doors, then they must be tested OPEN IN.

In real-world scenarios who knows which side of the door the fire could be?

Shouldn’t you then insist on a fire door assembly thats been tested on both sides and OPEN IN?

All hotel, apartment, guest house and b&b entrance doors to rooms or suites must be tested OPEN IN.

Get in touch!

- info@crisisfiredoors.co.za

- 060 771 5599

- 3 Amatuli, Eagle Road, Imbonini Industrial Park, Shakas Head, Kzn, South Africa, 4422